What We Do

Capabilities

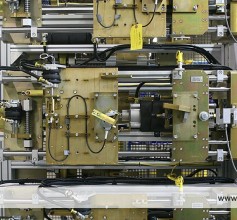

Our design capabilities can start with a concept or a copy of your electronic data in most of the common 2D, 3D Cad formats including .iges, .stp, .dwg, .dxf or SolidWorks file formats including .sldasm and .sldprt. In either case, our designers work as a team with your people from the initial meeting to the assembly phase to ensure that the specifications and performance of the finished product meets all of your requirements.

Excellent customer support is one of our main goals at PrimEq so we offer on site support any time our assistance is required and our quick response is one of our strengths.

PrimEq Design And Manufacturing Capabilities Include:

- Production pallet lines

- Vertical Presses

- Horizontal Presses

- Riveting Stations

- Fastening Stations

- Indexing Tables

- End of line testers

- Programmable Logic Controls and Data Acquisition Systems

- Automated vehicle systems simulators

- Durability and Extreme temperature test fixtures

Our manufacturing and testing solutions have assisted our customers to:

- Increase productivity of manufacturing facilities

- Ensure quality control

- Provide repeatable and controlled assembly and testing processes

- Reduce assembly and testing times

- Improve productivity for our customers

About Us

With 30yrs experience in mechanical engineering as well as high experience in the automotive industry. This allows us to supply highly competent assembly equipment and test machines.

PrimEq is committed at all levels of the company to total customer satisfaction. To meet this commitment we provide products and services that exceed customer expectations with quality and engineering at levels greater than any of our competitors. Also our product support is second to none.

- Qualified and experienced engineering staff

- High expertise level in automated production lines and assembly machines

- Innovative machine design and build for production processes

- Well-equipped facilities and a superior location

We can provide a single station to a full, multi-station manufacturing line – all within the ISO-9001 quality system.